The precise machining system of UV picosecond laser is a sort of machine applied in the fields of mechanical, basic subjects of engineering and technology science, materials science and mechanical engineering. Owing to the development of the picosecond fundamental frequency laser of high beam quality and high power, the power of UV picosecond laser has reached the level of 50W and the output records is constantly being broken. The continuously improved property of new nonlinear crystals has made great contributions to the stability and working lifetime of high power UV picosecond laser.

There are two removal ways when the laser is used for micro processing. The first way is the light and heat effect hat it the high energy laser is as a heat source to quickly heat the material and vaporize it, achieving the goal of removing material. The second way is the photochemical effect that the laser has enough high peak energy to break molecular bonds of material in the moment of touch and the material has been removed before the heat is accumulated. Compared to nanosecond laser, picosecond laser has shorter pulse width and higher peak power. The pulses of this kind of ultra fast laser can achieve a very ideal result of laser“cold”processing especially the pulse width in around 10ps. The wavelength of UV picosecond laser is even shorter and photon energy is higher. Thus smaller processing size and higher machining accuracy can be gained with UV picosecond laser.

Currently UV picosecond laser has quite obvious advantages in the aspects of organic polymer film metal thin film processing and the heat-affected zone of most applications can be controlled within 20µm or less.

Picosecond laser cutting machine is a kind of high precise cutting device used for metal and non-metallic thin material cutting. The cutting precision can reach micron level and is a way of cold processing with no burnt and rolled edge. It is widely used in the industries which has high requirements on cutting like aerospace, automotive manufacturing, medical treatment and consumer electronics. Good cutting effect, high efficiency, high precision has gained UV picosecond laser a lot of favors in different industries.

- Cut film material

The film material has very broad application in different industries and it can be divided into PET film, PI film, PP film and other plastic film and composite film of transparent material. UV picosecond laser cutting machine can be used for the precise cutting, drilling and etching of thin film materials and cutting, etching, trimming of composite film materials, achieving the full cut and half cut of covering film.

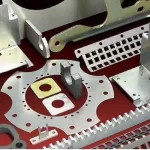

- Cutsilicon waferand ceramic material

The ceramic material is often used as the base material and has higher requirements on cutting in electronics industry. The cutting and clipping of alumina or zirconia ceramic substrate can be easily completed by picosecond laser cutting machine. picosecond laser cutting machine has significant advantage on aesthetics and accuracy.

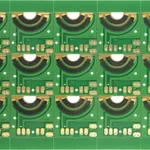

- Cut circuit Board

As the most widely used material in electronics industry, there are always higher requirements on the cutting accuracy and efficiency pf circuit board. The picosecond laser cutting machine can accomplish the precise cutting and splitting of the circuit board under 6mm thickness of different materials and substrates such as PCB, FR4, reinforcing steel, FPC, rigid-Flex Board, glass fiber board and etc.

- Cut thin metal material and glass material

Thin metal refers to metal materials under 0.2mm thickness like copper foil, aluminum foil, stainless steel, alloy materials and etc. The glass material is mainly 3C thin glass and processed by UV picosecond cutting machines will have no burrs, low carbonization, no deformation and small chipping. It has realized precise cutting and is used in the industries like military parts, and photovoltaic copper foil.