Femtosecond laser is the generating devices of ultra-short pulsed laser which emits laser in an ultra short time. The luminous time of the camera’s flash is about 1 microsecond while the ultra-short pulse of femtosecond laser emits laser in about one billionth of its time. As we all know, the speed of light is 300,000 kilometers per second but light moves forward by only 0.3 microns in 1 femtosecond.

Femtosecond laser has the following characteristics:

First of all the femtosecond laser lasts for very short time of only a few femtoseconds and it is thousands of times shorter than the shortest pulse derived with electronic methods which is the shortest pulse that humans can obtain under experimental condition.

Secondly femtosecond laser has high instantaneous power up to trillions of watts which is hundreds of times more than the total power generated all over the world.

Lastly, femtosecond laser can focus on the space area smaller than the diameter of hair, causing the intensity of electromagnetic field several times higher than the force of nucleus on surrounding electrons. And many of extreme physical conditions do not exist on earth and are impossible to gain by other ways. Due to ultra high peak power of femtosecond laser, the laser intensity can reach 1022W/cm² after focusing. The intensity far exceeds the internal interaction Coulomb field inside atom and consequently femtosecond laser pulse can easily release electrons can from atom and form plasma. For example, the Coulomb field intensity of hydrogen atom is 5*1011V/m while the femtosecond laser pulse of 1mJ can be 1012V/m after focusing so that the hydrogen atom can be ionized.

Femtosecond laser obtains short pulses by mode-locking technology on the femtosecond scale. Femtosecond laser is not monochromatic laser but a combination of laser whose wavelength continuously changes and central wavelength is around 800nm. The spatial coherence of the laser with continuous wavelength in this range is used to get great compression in time to gain the pulse output of femtosecond scale. The laser crystals are titanium gemstone crystals of wide laser spectrum.

Generally we can record instantaneous state of moving objects with flash photography.

In the same way, if a femtosecond laser is used to flash, it is possible to see every passage of the chemical reaction in the process at drastic rate.Thus femtosecond laser can be used to study the mystery of chemical reactions.

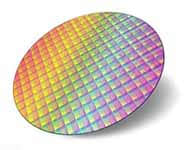

The most direct application of femtosecond pulsed laser is as laser source to form a variety of time-resolved spectroscopy, pumping and detection techniques. Its development has brought the research of physics, chemistry, biology, materials and information sciences into the field of microscopic ultrafast processes. It has created some brand new research fields such as femtosecond chemistry, quantum control chemistry, semiconductor coherent spectroscopy and etc.The combination of femtosecond pulsed laser and nano microscopy enables people to study the carrier dynamics in nanostructure like quantum wires, quantum dots and nanocrystals of semiconductor materials. In biology field, differential absorption spectroscopy and pumping/detection techniques provided by femtosecond laser technology are being used to study the energy transfer, energy transfer and charge separation processes of photosynthetic reaction centers. Ultra-short pulse laser is also applied in transmission, processing and storage of information.

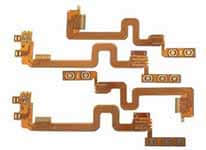

Another important application of femtosecond laser is microfabrication. The femtosecond laser pulse with pulse width of only one of thousand trillions seconds has unique characteristics on material processing. For example it has small or almost no melting zone for processing aperture and is used to microprocess and engrave on a variety of materials such as metals, semiconductors, transparent materials and even biological tissues. The processing area can be smaller than the focusing size and the diffraction limit can be broken through. Femtosecond laser is now used by some automobile manufacturers and heavy equipment processing plants to process engine fuel nozzles in better way. Small holes of hundreds of nanometers width can be made on the metal with ultra-short pulse laser.