In recent years, laser processing technology has been more and more widely used in the field of processing and handling of macromolecular material because of high machining accuracy, low damage, high efficiency and easy for automation.

In the field of macromolecular material processing and handling, it mainly includes:

- Laser welding refers to the processing method of combining two or more substances (likemetals or non-metals) together via high energy density generated by the laser. It is a kind of efficient, non-contact and non-destructive welding method. It has the characteristics of high efficiency and fast speed. It has been widely used in deep hole welding of metal materials and non-metallic materials, rapid connection of metal and non-metallic materials and surface handling of plastics and metal or non-metallic materials.

- Laser cleaning:Scan the surface of materials with laser beam to cause a certain degree of oxidation and corrosion on the surface so as to achieve the cleaning purpose. This method is mainly suitable for materials with coating layers and coatings on the surface such as plastic films, coatings and plastic composite materials.

- Laser printing refers to a processing method that uses a laser to print ink or pigments onto the surface of target object.It has the characteristics of high machining accuracy, fast speed and no contact, so it is widely used in manufacturing of high precision industry.

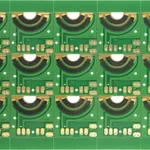

- Laser marking is a kind of processing method that uses a laser beam to mark text or graphics on objectsand then achieve the purpose of identification or positioning. It has the characteristics of high machining accuracy, fast speed, low damage and high efficiency, so it is widely used in the fields of surface marking and anti-counterfeiting technology of plastic products and metal products.

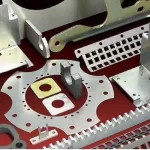

- Laser etching meansthe process of using a laser beam to ablate a certain area or depth of the object surface. With this method the surface of the objects can be cut, punch, polish or etch in various shapes as needed.

- Laser heat treatment refers to using the laser partiallyheat metal or non-metallic materials to soften or melt them in orderto improve the property of materials. This method has the features of fast processing speed, uniform heating and small heat affected zone, so it has been widely used in the heat treatment process of metal materials.

- Laser-assisted chemical corrosion uses laser beam to interact withmaterial to cause chemical reaction on the surface of materialand remove substances on the surface. This way is mainly applicable for materials with coating layers or coatings on the surface such as plastics, rubber, glass and fibers.

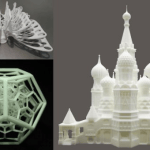

- Laser additive manufacturing technology isa technology whichgathers high density materials into three dimensional entities with a certain geometric shape through laser processing. It is widely used in the processing and manufacturing of metal materials owing to the characteristics of fast processing speed, high precision and low environmental pollution.

- Laser-assisted molecular design is the technology that uses laser beam to modify macromolecular materials in order to change their properties or give them new functions.This wayis mainly suitable for the presence of active groups of different groups, functional groups or structures in macromolecular materials such as macromolecular compounds, proteins and nucleic acids.

The wavelength of green picosecond laser is 532nm. Green laser is visible and can pass through coating layer of filter. By objective lens or filament formation, it can focus inside glass and destroy the internal stress of glass so as to achieve the purpose of cutting