As carbon neutrality has become the consensus of major global economies, the installed capacity of photovoltaic modules has increased rapidly. At present, the new trend of photovoltaic glass installation is that the structure of double-sided glass tends to be mainstream. On one hand, the structure of double-sided glass can reflect energy by the way that the sun directly reflects to the ground. On the other hand, it can use the multiple rows of photovoltaic glass panels to reflect energy from the rear to the front. This structure is conducive to improving the overall energy of installation.

The main feature of double-sided components is to bring additional gain by generating electricity in the rear of it and the power generation capacity of photovoltaic power plants can be effectively increased in the regions of same area. Even though there is little increase in costs , the ratio of input-output to gains can exceed 10 times. For example, if the installation is reasonable, the increase of power generation in the regions of specific latitudes can be increased by 20% with the current technology.

Double-glass components is a kind of packaging method for double-sided components with the highest efficiency. It has the advantages of water vapor resistance, corrosion resistance, wind and sand resistance, low attenuation rate, long lifetime and easy for cleaning. As the price of ultra thin glass drops to a reasonable level, the market share of double glass components is expected to be continuously increased in the future.

The emergence of new technologies can bring considerable profits to the gains of the regions of high latitudes in our country. At present, the annual growth rate of photovoltaic has risen rapidly and roughly as large as 100GW per year.

With the development of scientific and technological level and the increase of market demands, the laser applications in photovoltaic industry has become more extensive and diverse.

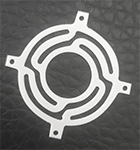

Backplane glass drilling is one of the key technologies in production of photovoltaic glass. It aims at solving the shortcomings of traditional mechanical drilling such as large dust, long working hours, poor chipping result and unable to process special shaped holes.

INNGU GXS series IR subnanosecond laser has adopted the scheme of multi stage amplification and rationally distributed the gains at all levels. Compared with similar laser products, the processing efficiency and process indicators have been greatly improved because of small drilling chipping, high machining accuracy, high efficiency and high tempering yield.

Regarding the chipping coefficient of laser, bubbles or scratches and cracks above 0.3 are usually not allowed on the surface of national standard tempered glass. If out of this data, the tempered processing will produce waste and meanwhile it is inevitable for the explosion caused by poor tempering processing under hot environment.

INNGU GXS series IR subnanosecond laser has solved the issue of thermal effect well by the way of water cooling for heat dissipation, ensuring the stability and lifetime of laser. This kind of laser can adapt to complex environments of high temperature and high humidity for photovoltaic glass drilling. After test, it is found that GXS series IR subnanosecond laser can keep running and working normally and stably under the ambient temperature from minus 5℃ to 45℃.

INNGU IR subnanosecond laser has compact structure and smart size. Depending on the advantages of high peak power and excellent beam quality, the processing effect of IR subnanosecond laser is better than that of other nanosecond pulsed lasers of the same type. It is mainly used in laser processing fields like semiconductor and photovoltaic industries, especially for glass drilling and has greatly improved processing efficiency.

In the future, INNGU Laser will continue developing and upgrading products to optimize output performance. At the same time, the proportion of domestic and independent components will be increased to reduce production costs and broaden the application fields.