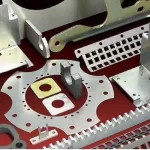

With the improvement of the automation degree of industrial production, the requirements for machining accuracy are also becoming higher and higher. With traditional processing technology, the material is processed through tools after heating and melting. It is required that the material is quickly cooled and formed after melting so that the material has higher strength and hardness. However, traditional processing techniques will produce the issues like plenty of dust, pollution, noise and etc. And due to insufficient cutting accuracy, the surface of product is rough and prone to defects like burrs, affecting the appearance and quality of product. Processing by high power IR picosecond laser has the following advantages:

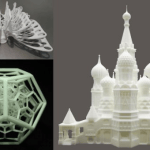

1.High processing accuracy. The processing accuracy of traditional processes can only reach micron while high power IR picosecond laser can reach nano level.

2.Small heat effect. As the melting degree of material is very small with high power IR picosecond laser for processing, there will be no deformation and cracks of material caused by solidification and contraction after melting and the processing quality is good.

3.No damage. It will neither cause thermal damage to material nor affect the appearance and quality of the product.

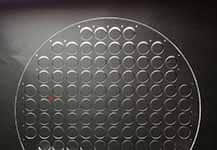

4.High work efficiency. The work efficiency is high as multiple workpieces can be processed at the same time.

5.Easy to maintain. No auxiliary equipment is required when using IR picosecond laser for processing. So it is very convenient to maintain and saves a lot in labour power, material and money.

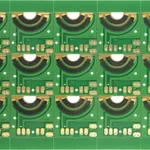

In industrial applications, the laser equipment is needed for high precision machining. For equipment in some applications, it is necessary to use IR picosecond lasers. Therefore, the market of IR picosecond laser is very broad. And the development prospects of IR picosecond laser are mainly reflected in the following aspects:

- IR Picosecond laser is highend laser machine with broad prospects of market demand. With the improvement of people’s living standards and demands on upgrade consumption, consumers’ requirements for products are also getting higher and higher. As the requirements of high-end products on quality and performance are much higher than that of ordinary products, the market demand on high-end laser equipment is constantly growing especially for IR picosecond At the same time, due to the improvement of people’s requirements on product quality and performance, traditional laser equipment can no longer meet the needs of production and upgradation must be carried out to meet market demand. Thus, the picosecond laser equipment will become a new hot concern in the market.

- There is high technology needed and great difficulity in R&D for IR picosecond laser

—————————————————————————————————————————————————————————————————————————————————————

On one hand, due to the high technology, many manufacturers are unwilling to invest in R&D and production. On the other hand, IR picosecond laser equipment has fierce competition due to uneven quality in current market. Therefore, IR picosecond laser needs continuous breakthroughs in technology and quality in order to better meet market demands.