Picosecond laser refers to the laser with adjustable picosecond pulse width and repetition frequency. Compared with nanosecond laser, the picosecond pulse width is on the order of picosecond, the repetition frequency on the order of kilohertz and the pulse width on the order of nanosecond. Our GXP series green picosecond laser has superior beam quality, compact structure, reliable performance, high work efficiency, high brightness and small focusing spot. It is mainly in semiconductor and photovoltaic industries, macromolecular materials processing and etc.

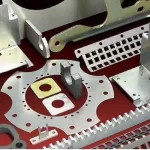

- Semiconductor industry

The semiconductor industry is only an important economic pillar of a country but also one of the important symbols of a country’s scientific and technological level as well as comprehensive national strength. China has the world’s largest semiconductor production base but many semiconductor companies have introduced advanced technology and equipment with high energy pulse outputs at picosecond or nanosecond level from abroad.

- Photovoltaic industry

The photovoltaic industry is an emerging industry which converts light energy into electrical energy through solar cells. As a national strategic emerging industry, it has the characteristics of a wide range of products, long industrial chain, a wide range of applications and high scientific and technological content. It has become the most dynamic and potential component of China’s new energy industries. At present, the world’s largest photovoltaic industry system has been built in China. However, it is now facing the problems such as overcapacity, fierce market competition, low product technology and high production costs. With the advancement of technology and improvement of management level, the photovoltaic industry will have larger space for development.

- Processing and treatment of macromolecularmaterials

With the development of our country’s economy and society and improvement of people’s living standards, people’s requirements for life quality are getting higher and higher. Due to the increasingly serious problems of pollution and environmental destruction which is caused by traditional material processing technologies, people have put forward higher requirements for material processing and handling. Macromolecular material is a typical renewable resource of the characteristics of renewable, non-polluting and recyclable. With the enhancement of people’s environmental awareness, the processing and handling technology of macromolecular materials has been applied more widely and deeply. Macromolecular material processing and handling technology refers to the laser technology of cutting, punching, welding, polishing, etching and modification.

Here are the advantages of processing by green picosecond laser.

- Non-contact processing: Onlylaser beam hascontact with processed parts for laser processing and no cutting force is used to the cut parts which avoids the damage to the surface of processed materials.

- Highmachining accuracy and low heat impact: Pulsed lasers can haveextremely high instantaneous power, extremely high energy density and very low average power. Processing can be completed instantly and the heat affected zone is very small, ensuring high precision machining and small heat impact.

- High processing efficiencyandgood economic benefits: The efficiency of laser processing is always several times that of mechanical processing and there are no consumables and no pollution.

- High processing safety and low labor cost.