Green nanosecond laser, as an advanced laser technology device, plays an important role in scientific research, medical treatment and industrial applications. It is highly regarded for its efficiency, accuracy and reliability. Green nanosecond laser is a kind of equipment that generates green laser beam by using laser technology. Its core component is the laser medium, through the input of current or light energy, stimulate the atoms or molecules in the medium to transition to a high energy level, and then under the stimulation of the outside world, from a high energy level to a low energy level, thereby releasing laser photons. These photons are adjusted and enhanced by the optical system, and finally form a high-quality green laser beam.

Green nanosecond lasers have several advantages. First, it has an extremely high beam quality, a uniform spot and a high focus, allowing it to provide precise lighting conditions in scientific experiments. Secondly, green lasers have a higher light absorption rate and can better interact with substances, thus playing an important role in fields such as material processing and medical treatment. In addition, the green nanosecond laser also has the characteristics of high efficiency, which can complete the laser output in a very short time and improve the work efficiency.

In the field of scientific research, green nanosecond lasers are widely used in spectral analysis, precision measurement and physical experiments. It can provide a high energy, high stability of the laser light source, for scientists to carry out a variety of experiments to provide reliable support. For example, in spectral analysis, green lasers can produce high-brightness beams that make spectral images clearly visible, helping scientists study the structure and properties of matter. In precision measurement, the high precision and stability of green laser can provide accurate measurement results, providing reliable data support for scientific research.

In the field of medicine, green nanosecond lasers are widely used in laser surgery and skin cosmetology. Its high energy and high absorption rate enable the green laser to complete tissue cutting and coagulation in a very short time, thus enabling precise surgical operations. At the same time, the green laser can also effectively remove the pigmentation and vascular lesions on the skin, improve the skin quality and improve the cosmetic effect. Therefore, the green nanosecond laser has a broad application prospect in medical treatment.

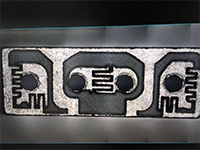

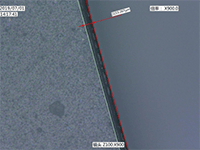

In the field of industrial applications, green nanosecond lasers are used in material processing and precision manufacturing. Its high energy and high focusing characteristics enable the green laser to process materials efficiently and accurately. For example, in microelectronics manufacturing, green lasers enable precise etching and welding, improving the manufacturing quality and reliability of chips. In precision manufacturing, green laser can achieve micron-level processing accuracy to meet the manufacturing needs of high-precision parts.

In short, as an advanced laser technology device, green nanosecond laser has a wide range of application prospects in scientific research, medical treatment and industrial applications. Its high efficiency, accuracy and reliability make it play an important role in various fields. With the continuous progress and innovation of science and technology, it is believed that green nanosecond lasers will show a broader space for development in the future.