For some special industries, only high power IR picosecond laser equipment can complete processing tasks. Currently high power IR picosecond laser processing equipment is mainly used in the fields of industry, medical treatment, aerospace, automobile, electronics and etc.

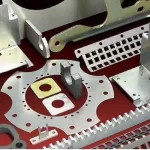

In automotive industry, when making and manufacturing body stamping parts with traditional techniques, the metal material is melted after heating first and then processed by tools. This technique requires material to be quickly cooled and formed after melting so that the material has higher strength and hardness. However, with high power IR picosecond for processing, the material does not need to be heated and melted but cut and engraved directly on the surface due to the short wavelength. The equipment has been widely used in the field of automobile manufacturing and has achieved good results.

Advantages of high power IR picosecond lasers for processing in industrial applications:

- High precision.Processing by high power picosecond laser can acquire high accuracy and fineness, deep cutting and engraving of product and little damage and deformation on surface, ensuring the appearance quality and performance of

- No dust pollution.Traditional techniques requires a lot of water or acid cleaning equipment to clean the surface of workpieces, which has caused a great deal of waste of resources and environmental pollution. Nevertheless, Processing by high power picosecond laser will not produce dust pollution and need acid cleaning equipment as well as no secondary pollution to the environment because of anhydrous cleaning.

- Save time and cost.Traditional techniques takes about 8 hours to process a workpiece while it only takes 3-4 hours to complete the processing and production of a workpiece with high power IR picosecond laser, greatly improving production efficiency and product quality.

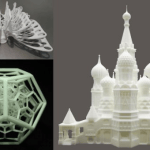

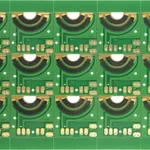

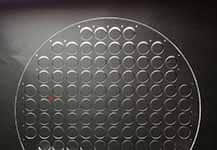

INNGU IR picosecond laser adopts all-in-one design with compact structure, great stability and high reliability. High power output can be achieved for whole machine with picosecond optical fiber seed source and free space solid state amplifier. Compared to traditional solid state seed source, the independently developed optical fiber seed source has more flexible output parameters and better performance in stability and the space solid state amplifier guarantees high peak power output. Our GXP series IR picosecond laser is mainly applied in the fields like high precision industry, aerospace, shipbuilding, automobile manufacturing and etc. IR picosecond laser is used for metal sheet etching, glass cutting and drilling in 3D industry, drilling on fuel nozzle drilling and heat sink of aero engine, sapphire engraving and so on. Compared with conventional IR lasers, traditional laser technology is mature but both of them have limitations.The main advantage of IR lasers is the short wavelength which can reach micron or even nano level accuracy so it can be used in many high fields of precision manufacturing.