Abstract

The Thin Disk Laser, a transformative solid-state laser architecture, has redefined the performance limits for high-power laser systems since its conception in the 1990s. By ingeniously addressing the fundamental challenge of thermal management, it delivers an unparalleled combination of high output power and exceptional beam quality. This article explores the development, operational principles, and far-reaching applications of this technology, which has become a critical enabler in advanced manufacturing, scientific research, and medical technology.

1. Introduction: Breaking the Thermal Barrier

For decades, scaling the output power of solid-state lasers was fundamentally constrained by thermal effects. The heat generated within the traditional rod or slab-shaped gain medium creates significant temperature gradients, leading to thermal lensing, birefringence, and ultimately, beam distortion. This thermal barrier imposed a strict trade-off between power and beam quality.

The Thin Disk Laser, pioneered by the group of Adolf Giesen at the University of Stuttgart, Germany, presented an elegant solution. Its revolutionary design shifts the paradigm of heat removal, allowing it to circumvent these limitations and set new benchmarks for brightness (power per unit area per unit solid angle), a key metric for material processing.

2. The Core Innovation: Principles of Operation

The breakthrough lies in a radically different gain medium geometry and cooling scheme.

-

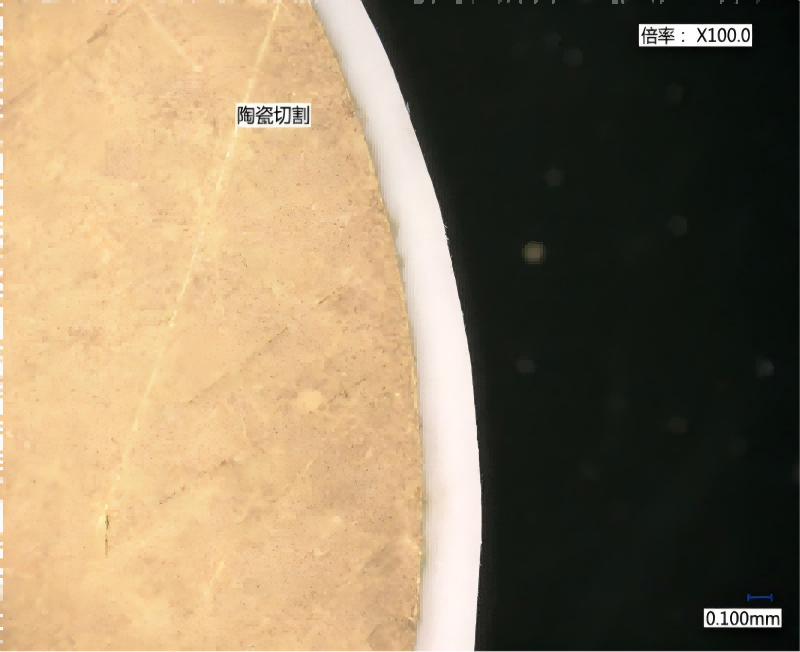

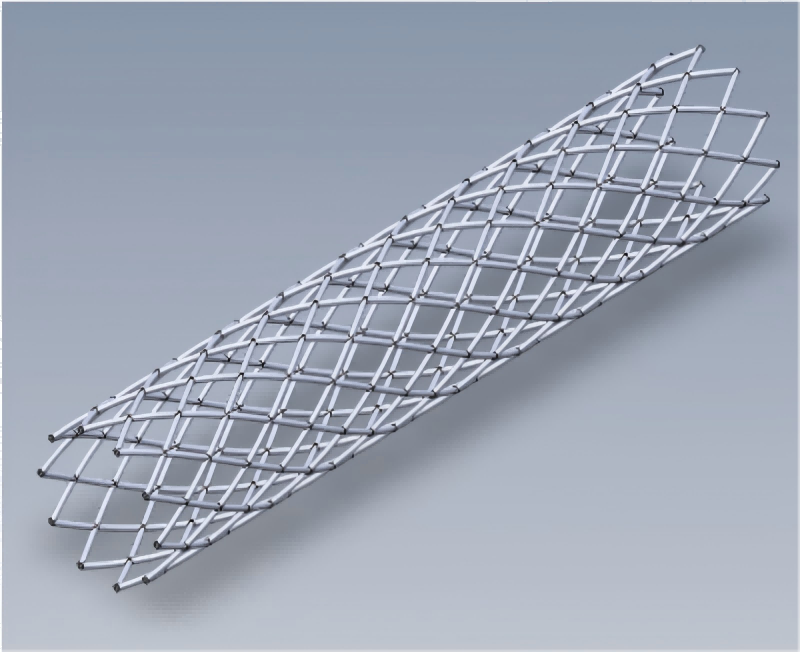

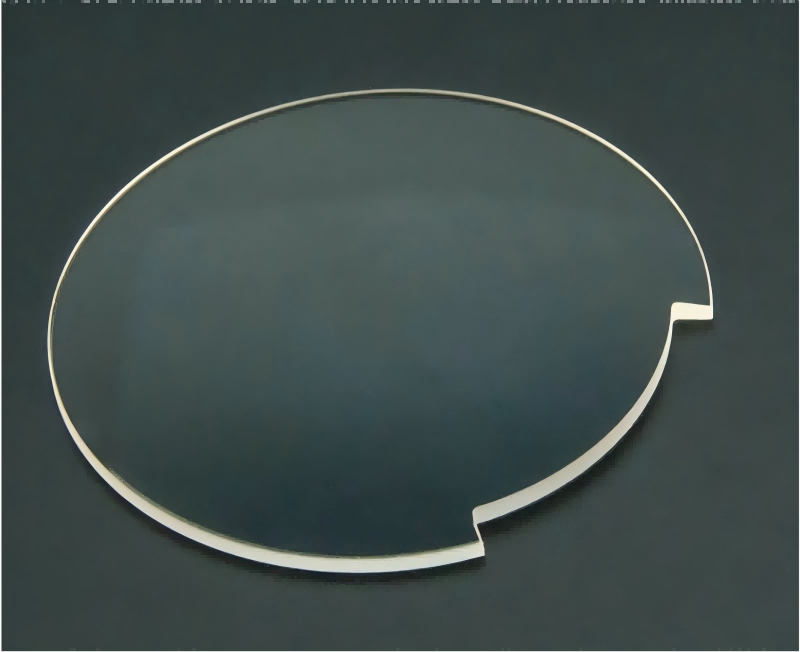

Gain Medium Geometry: The active medium is a single crystal disk (e.g., Yb:YAG) with a thickness of only 100–400 µm and a diameter of several millimeters to over a centimeter. This creates an extremely high surface-to-volume ratio.

-

Backside Cooling: The thin disk is mounted, via a soldered or diffusion-bonded interface, directly onto a highly efficient heat sink (often diamond or copper). Crucially, cooling is applied only to the rear face of the disk.

-

Heat Flow Management: Pump light is delivered through the disk multiple times (multipass pumping, typically 16-32 passes) to achieve high absorption. The generated heat flows parallel to the laser beam axis—through the minimal thickness of the disk and into the heat sink. This nearly eliminates the radial temperature gradients that cause thermal lensing.

-

Resonator Design: The disk acts as one end mirror of the laser resonator (often in a folded “Z” configuration). This design, combined with the minimal thermal distortion, allows the laser to operate with a very low fundamental mode volume, enabling diffraction-limited beam quality even at multi-kilowatt power levels.

3. Historical Development and Milestones

-

1990s – Conceptualization and Proof-of-Principle: The foundational work at the University of Stuttgart demonstrated the first Yb:YAG thin disk laser, achieving output powers in the tens-of-watts range with outstanding efficiency and beam quality.

-

2000s – Power Scaling and Commercialization: Intensive research focused on scaling laws, improved pump modules, and advanced disk mounting techniques. Companies like TRUMPF (Germany) drove commercialization. Milestones included the first kilowatt-class systems and, by 2009, a single-disk system achieving 10 kW of output power.

-

2010s – Diversification and Application Expansion: The technology matured. Product lines diversified into different power classes (from <1 kW to >10 kW), pulse regimes (continuous wave, nanosecond, picosecond, femtosecond), and wavelengths (via frequency conversion). It became a mainstream tool in automotive and aerospace manufacturing.

-

2020s – Towards Higher Peaks and New Frontiers: Current research pushes boundaries in ultra-high peak power (for scientific applications), further power scaling with multi-disk modules, and integration with intelligent, adaptive control systems for next-generation industrial applications.

4. Key Advantages and Performance Characteristics

-

Unmatched Beam Quality at High Power: The primary advantage. Thin Disk Lasers maintain a beam propagation factor (M²) very close to 1.0 across their entire power range, enabling extremely small, high-intensity focal spots.

-

High Efficiency: Excellent quantum efficiency of materials like Yb:YAG, combined with efficient pump absorption, leads to optical-to-optical efficiencies exceeding 50% and wall-plug efficiencies over 30%.

-

Compact and Scalable Design: The modular disk concept allows power scaling by increasing pump spot size or by combining multiple disks in series within a single resonator.

-

Robustness and Reliability: The solid-state design, without delicate fibers prone to degradation at high powers (a concern for some high-power fiber lasers), offers high long-term stability. The gain medium itself has an exceptionally long lifetime.

5. Broad Spectrum of Applications

A. Advanced Manufacturing (The Core Market)

-

Precision Cutting & Welding: Its high brightness allows for deep-penetration welding with superior seam quality and high aspect ratios, and fine cutting with minimal kerf width. It is indispensable for welding aluminum, copper, and high-strength steels in electric vehicle battery production, automotive bodies, and aerospace components (e.g., Airbus A350 fuselage frames).

-

Remote Processing: Excellent beam quality is maintained over long optical paths, enabling fast, precise ablation, welding, and cutting using scanning galvanometers from distances of over a meter.

-

Additive Manufacturing (3D Printing): Provides the precise energy density needed for high-resolution, fully dense metal part production.

B. Scientific Research

-

Pump Source for Ultra-High-Power Systems: Serves as the robust and high-quality pre-amplifier stage for petawatt-class chirped-pulse amplification (CPA) systems used in laser-plasma and attosecond science.

-

Frequency Metrology: Its intrinsic stability makes it suitable for use in optical clocks and precision spectroscopy.

-

Nonlinear Optics: High peak powers from pulsed thin disk oscillators and amplifiers are ideal for efficient frequency conversion into the UV and generation of supercontinuum spectra.

C. Medical Technology

-

Surgery: Pulsed Thulium-doped (Tm) thin disk lasers emitting around 2 µm are ideal for soft tissue ablation (urology, ENT) due to strong water absorption, offering precise cutting with minimal thermal damage and hemostasis.

-

Ophthalmology: Frequency-doubled systems provide the precise green wavelengths needed for retinal photocoagulation.

D. Emerging & Niche Applications

-

Space Debris Tracking and Satellite Communication: The near-diffraction-limited beam enables efficient long-range transmission through the atmosphere for LIDAR and free-space optical communication.

-

Quantum Technology: As a highly stable pump source for parametric down-conversion to generate entangled photon pairs.

6. Current Challenges and Future Perspectives

Despite its success, the technology faces challenges:

-

Cost Complexity: The precision optics and multi-pass pump modules contribute to a higher initial cost compared to some high-power fiber lasers.

-

Pumping Complexity: Achieving uniform, high-intensity pumping across the disk requires sophisticated optical designs.

Future directions are promising:

-

Power Scaling Beyond Single Disks: Multi-disk modules and novel composite materials aim to push continuous-wave power towards 50-100 kW.

-

New Gain Materials: Research into ceramics (Yb:LuAG) and other crystals (Yb:CaF₂) seeks to improve thermal and laser properties further.

-

Ultrashort Pulses at High Average Power: Continued development of thin disk technology for femtosecond pulses at kilowatt average powers, revolutionizing “cold” ablation processes.

-

System Intelligence: Integration with real-time beam monitoring and AI-driven process control to maximize performance and ease of use.

7. Conclusion

The Thin Disk Laser stands as a landmark achievement in laser physics and engineering. By mastering thermal management through a simple yet profound geometric change, it has effectively decoupled high power from poor beam quality. It has transitioned from a laboratory curiosity to a cornerstone technology powering some of the most demanding industrial and scientific applications. As research continues to refine its capabilities and reduce costs, the Thin Disk Laser is poised to remain at the forefront of photonic technology, enabling future innovations that demand nothing less than the perfect beam.