Glass, as an important industrial material, is widely used in the fields of automotive, construction, medical treatment, display, electronic products and etc. The speed of laser processing will be different due to different thickness of applied glass. Femtosecond laser has unique advantages in glass processing because of high brightness, small focusing spots and small heat-affected zone.

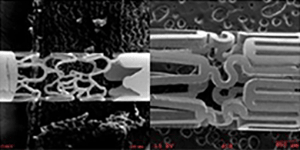

Ultrafast lasers have the characteristics of short pulse width and high peak power. When acting with transparent materials like glass, nonlinear effects will be produced such as nonlinear ionization and self-focusing. The characteristic has been widely used in the processing of transparent materials. When welding glass with continuous and long-pulse lasers, it is often necessary to add an absorption layer and the high thermal impact makes it difficult to achieve high-quality welding.

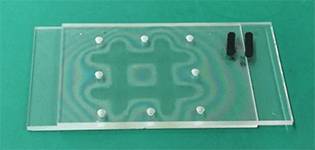

In 2005, researchers used femtosecond lasers to successfully weld glass for the first time. At present, researchers at home and abroad have realized ultra-fast laser welding of various glasses such as quartz glass, photosensitive glass, borosilicate glass, soda-lime glass, and non-alkali aluminosilicate glass, and obtained high connection strength.

However, ultra-fast laser glass welding has very demanding requirements for clearance. It is usually necessary to form optical contact between the glasses through external forces or fixtures which means the gap is less than 1/4 of the wavelength. After strict cleaning of the glass, it is difficult to achieve large-area optical contact. In addition, the ultra-fast laser welding of glass has more demanding requirements for clearance. The ultra-fast laser welding of the glass is greatly restricted in engineering applications due to the combined effect of the two aspects. How to achieve ultra-fast laser welding of glass in non-optical contact has become a hot research topic in recent years.

In order to achieve intensity threshold of nonlinear absorption light of glass, the microscopic objective lens of large numerical aperture is usually used to focus the laser beam when welding glass with ultra-fast lasers. However, it is not conducive to the promotion and application of welding process in industry. On the one hand, the short focal length(usually in the order of millimeters) limits the thickness of the glass and the shallow depth of focus makes it demand on the the position of the focus point during welding. On the other hand, the small diameter of focusing spot(usually only a few microns) and the narrow width of weld causes the carrying capacity of the weld weak.

Owing to the large photon energy of femtosecond laser, the nonlinear absorption threshold can be reduced, thus long focal length and large spots can be used for welding. In addition, sufficient amount of glass materials can be melted to fill the gap. Therefore, femtosecond laser can realize continuous seam welding of glass in non-optical contact.

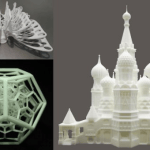

At present, femtosecond laser has been applied in a wide range of fields such as physics, chemistry, life sciences, medical treatment and engineering especially in the field of optics and electronics. There are also new possibilities of applications in the fields of communications, computers and energy. The intensity of laser can transmit a large amount of information from one place to another almost no loss, inducing further high speeds in optical communication. Femtosecond laser also has brought huge impact in the field of nuclear physics. Pulsed laser has so strong electric field that it is possible to accelerate electrons to be close to the speed of light in 1 femtosecond. There it can be used as “accelerator” to accelerate electrons.

With further development of the laser technology of ultra-short pulse laser and improvement of commercial femtosecond laser with high reliability, there will definitely have wider applications for femtosecond laser in more fields.