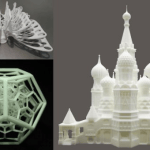

Compared with nanosecond laser, the pulse width of picosecond laser is shorter especially the laser pulses less than 10ps has no thermal damage when processing materials which is called as “cold processing”, widely used in precision machining field. UV Picosecond laser has shorter wavelength, higher Photon Energy and smaller focus spot. The UV photon of high energy directly breaks the molecular bond of material and will not generate the hot melt process of IR laser. As a result, the processing size can be smaller and machining accuracy has been further improved.

The pulse time of picosecond laser cutting machine is particularly short and the single pulse duration is only a few picoseconds. Therefore, the thermal effect is very small and even negligible. With respect to the processing of laser cutting machine, there is no need to recast material during whole process and the process is clean. And the absorption of laser energy is not affected by material and wavelength. Accordingly, picosecond laser cutting machine and femtosecond Laser cutting machine of ultra fast laser processing system have broad space in the field of micro precise laser processing. Picosecond laser cutting machine has larger application market than nanosecond laser cutting machine such as solar cells, OLED laser cutting, OLED laser cutting, brittle material drilling and etc. Compared to the thermal range and effects of material in nanosecond range , picosecond laser almost has no thermal effect and has better result. At the same time, it also just needs shorter time but higher accuracy and faster processing speed.

Although now there is mainly nanosecond laser cutting machine for laser cutting machine, micro-precision laser processing equipment must be applied in more industries as the precise cutting technology is developing rapidly and the requirements for laser cutting equipment are becoming higher and higher.

Picosecond laser cutting machine is mainly composed of picosecond laser, laser guide, displacement platform, focusing system, computer control system and other auxiliary systems. Picosecond laser is the ultra-short pulse laser of high peak value. The principle is that the laser beam is emitted to the workpiece after focusing and the instantaneous energy heats the material to melt or evaporate them.

The main advantages of picosecond laser are as follows.

- Coldprocessing and almost no carbonization;

- Ultrashort pulses and release energy in picosecond time, smallheat affected zone and no micro cracks;

- Fast Picosecond laser has high repetition frequency and the speed of galvanometer speed is fast;

- Precise cutting effect is fine. Picosecond laser uses singlepulse energy for high frequency processin and the processing surface is more fine;

- Suitable for processing various materials;

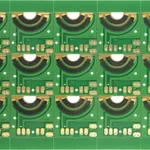

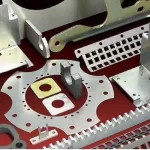

- Die cutting, marking, drilling, etching, half cut, full cut, scribing and grooving of ultrathin metal materials(copper, gold, silver, aluminum, nickel, titanium, stainless steel, molybdenum), flexible materials(PET, PI, PVC, PP, magnetic film, Teflon, plastic film), graphene, siliconwafer, ceramic, carbon fiber, FPC and other materials.