Introduction

Laser marking has evolved as a crucial technology across industries, enabling permanent identification, branding, and traceability on various materials. The 20W UV Nanosecond Laser represents a significant advancement in laser technology, offering unique characteristics that revolutionize marking techniques in numerous applications.

Understanding Laser Marking

Laser marking involves utilizing lasers to create marks on surfaces by altering their properties or appearance. This method ensures high precision, non-contact processing, and the durability of marks. Different techniques, such as engraving, annealing, foaming, and ablation, contribute to diverse marking results essential in industries like manufacturing, electronics, and healthcare.

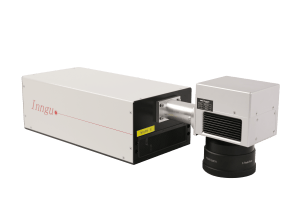

Overview of 20W UV Nanosecond Laser

The 20W UV Nanosecond Laser operates in the ultraviolet spectrum, emitting short pulses in the nanosecond range. Its high peak power and short pulse duration enable exceptional precision, making it a preferred choice for various marking applications. Compared to other lasers, its shorter wavelength offers advantages in marking certain materials and achieving finer details.

Influence of 20W UV Nanosecond Laser on Laser Marking Techniques

Enhanced Precision and Accuracy

The ultra-short pulses emitted by the 20W UV Nanosecond Laser allow for unparalleled precision in laser marking. The nanosecond pulse duration enables fine control over the laser’s energy deposition, resulting in precise and detailed markings. This level of accuracy is indispensable in industries like aerospace, where part identification codes or serial numbers must be precise for safety and traceability.

Furthermore, the laser’s exceptional accuracy allows for the creation of high-resolution graphics, logos, and complex patterns on various materials. In applications where aesthetic appeal or branding is crucial, such as luxury goods or consumer electronics, the 20W UV Nanosecond Laser’s precision plays a vital role in achieving intricate designs.

Materials Processing and Versatility

The versatility of the 20W UV Nanosecond Laser extends across a broad spectrum of materials. It can efficiently mark metals, including stainless steel, aluminum, and titanium, with high contrast and readability. Additionally, it demonstrates remarkable capabilities in marking plastics, ceramics, glass, and even some organic materials, offering diverse applications in industries ranging from automotive to medical devices.

Its adaptability to different surfaces and materials is a testament to its flexibility, making it a preferred choice for manufacturers seeking a single solution for marking various products.

Speed and Efficiency

The high-speed processing capability of the 20W UV Nanosecond Laser significantly enhances efficiency in production environments. The rapid marking speeds, coupled with their precision, allow for increased throughput and reduced cycle times. This attribute is particularly advantageous in mass production scenarios, where high volumes of products need to be marked quickly without compromising quality.

In industries like packaging or electronics assembly, where continuous production lines operate, the laser’s efficiency in marking helps maintain workflow continuity and meets stringent manufacturing demands.

Reduced Thermal Impact

The 20W UV Nanosecond Laser’s capability to minimize thermal impact during the marking process is a pivotal factor that distinguishes it in various industrial applications. By emitting ultrashort pulses in the nanosecond range, this laser significantly reduces heat transfer to the surrounding material.

Importance in Electronics and Sensitive Materials

In industries such as electronics manufacturing, where precise marking on sensitive components is crucial, the 20W UV Nanosecond Laser’s reduced thermal effect is indispensable. Delicate electronic components, like semiconductors or microcircuits, are susceptible to heat damage during marking processes. However, the shorter pulse duration of the UV Nanosecond Laser prevents excessive heating, preserving the integrity of these components and ensuring their functionality.

Preservation of Material Properties

Moreover, this reduced thermal impact is advantageous in marking various materials without compromising their structural or chemical properties. For instance, in the medical field, the laser’s ability to mark surgical instruments or implants without altering their properties is essential for maintaining sterilization and biocompatibility.

Application Specifics and Case Studies

Automotive Industry: Part Identification and Traceability

One notable application of the 20W UV Nanosecond Laser is in the automotive sector. The laser’s precision and speed are utilized for marking identification codes, serial numbers, or logos on automotive parts. These marks ensure traceability, aiding in quality control and supply chain management. Case studies reveal enhanced efficiency in part identification and reliable traceability across manufacturing stages.

Consumer Electronics: Aesthetic Marking and Branding

In consumer electronics, the laser’s ability to create high-resolution and intricate marks is leveraged for aesthetic purposes. Products like smartphones, laptops, or wearables often feature company logos, serial numbers, or decorative elements, which require precision and aesthetic appeal. Case studies showcase how the 20W UV Nanosecond Laser facilitates the creation of fine and detailed markings, contributing to product branding and visual appeal.

Future Prospects and Advancements

While the 20W UV Nanosecond Laser is already a leading technology in laser marking, ongoing research aims to further refine its capabilities. One area of interest is beam quality enhancement. Improving beam characteristics, such as beam profile uniformity and focus stability, can advance marking precision and consistency, particularly in applications requiring fine details.

Moreover, advancements in control systems and software can enable more sophisticated mark designs and patterns, expanding the creative possibilities in laser marking. Integrating machine learning and AI algorithms could optimize marking parameters, enhance efficiency, and reduce setup times.

Conclusion

In conclusion, the 20W UV Nanosecond Laser’s influence on laser marking techniques is undeniable, revolutionizing precision, versatility, and efficiency across industries. As advancements continue, its impact will likely extend further, shaping manufacturing, traceability, and product identification in diverse sectors.

The adaptability and precision of this laser present an exciting future, paving the way for enhanced marking techniques that meet evolving industry demands. Continued innovation in laser technology promises to unlock new applications, fueling progress and transformation in the field of laser marking.